Newswise — Imagine having a device that acts as an insulator when it’s cool and can also be an excellent radiator of heat when it gets hot — a smart material that knows how to change its behavior to handle different temperatures.

Researchers at the Johns Hopkins Applied Physics Laboratory (APL), in Laurel, Maryland, have made a significant breakthrough in the development of advanced materials technology that can efficiently manage thermal conditions, particularly in buildings and data centers, offering a promising solution to mitigate the impact of energy consumption on climate change.

The research was outlined in “High Emissive Contrast of Adaptive, Thin-Film, Tungsten-Doped VO2 Composites,” published Aug. 15 in Applied Physics Letters. It focuses on adaptive, thin-film, tungsten-doped vanadium dioxide (VO2) composites that demonstrate high emissive contrast and tunable metal-insulator transition temperatures. The principal investigator for the technical project is Joe Miragliotta, who is working with APL’s Tech Transfer Office to transition the advanced materials technology to industry.

More than half the energy consumed in the American residential industry is spent on heating and cooling homes. And data centers — the buildings used to house critical computer systems and associated components, such as telecommunications and storage systems — spend more than 40% of their energy on thermal regulation for their electronics.

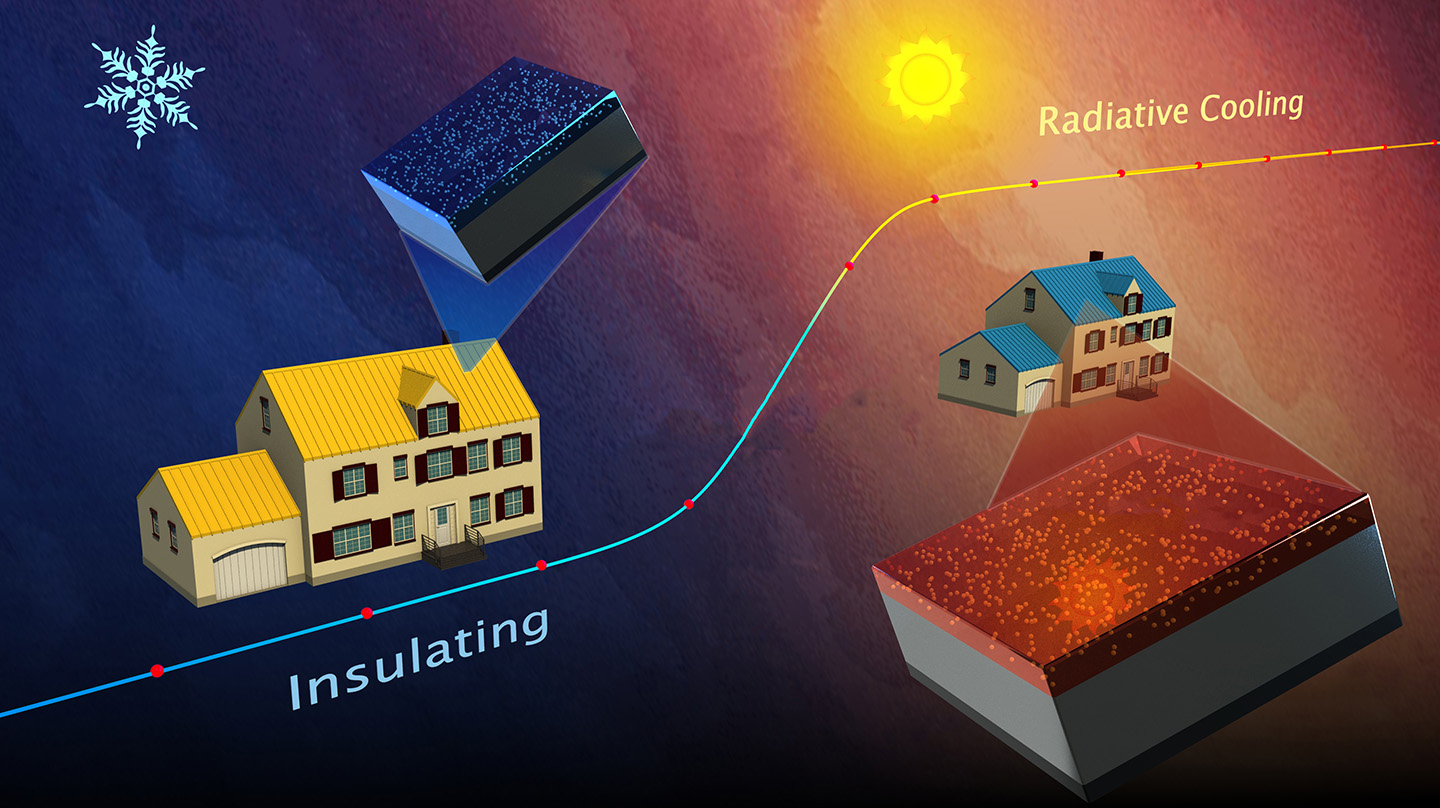

“Current thermal management solutions, such as radiative roofs, reflective window films and warm-water cooling systems, often lead to excess energy consumption or are limited in their efficiency,” explained David Shrekenhamer, the assistant program manager for the Physics, Electronic Materials and Devices program at APL, and a coauthor of the paper. “The development of passive and adaptive thermal management systems with high radiative efficiency at higher temperatures and effective insulation at lower temperatures has been a critical goal for researchers.”

Introducing Tungsten-Doped VO2 Composites

VO2 has emerged as a candidate material for adaptive thermal management because of its unique ability to transition from a low-temperature reflective state to a high-temperature emissive state at a specific temperature threshold (around 154°F, or 68°C). However, researchers have discovered that by “doping” VO2 with high-valence tungsten (W6+), the transition temperature can be reduced to near-room temperature (around 71°F, or 22°C), making it highly suitable for various thermal management applications.

Lead author Gabriella Hunt and her coauthors, who include collaborators at Plasmonics Inc., describe how they designed and demonstrated a multilayer film. They used computational tools to optimize the layer thickness and doping concentration to achieve a high emissive contrast — the difference in radiative efficiency between the low- and high-temperature states — while reducing the transition temperature.

Through a controlled fabrication process, the team deposited films with various thermal adaptive layer thicknesses and doping levels. By adjusting the dopant concentration and layer thickness, the team was able to achieve a tunable metal-insulator transition temperature, enabling the material’s efficient operation in various thermal management applications.

“With this smart material, we could have more efficient heating and cooling systems,” Shrekenhamer explained. “When it’s cold outside, the material acts as an insulator, helping to keep the warmth inside. But as soon as it gets hot, the material switches to being a radiator, allowing it to release excess heat and keep things cool.”

The Potential for Efficient Thermal Management

The research findings show great promise in revolutionizing thermal management technology, and represent a significant step in ongoing efforts to reduce energy consumption and combat climate change, Shrekenhamer said.

“Our research shows that we can use a dielectric material in our device, which normally causes some energy loss, without significantly degrading the efficiency of our device,” noted Hunt, a Ph.D. student in the materials science and engineering program at the Johns Hopkins Whiting School of Engineering. “We also provide information on the best design choices to optimize the efficiency of these devices at a range of temperatures. These discoveries are important for realizing commercial production of VO2-based devices that can be used across industries for a wide array of applications.”

The team plans to continue to explore other refinements to the process. “By continuing to enhance the operating optical contrast of these multilayer composites, we hope to further demonstrate the broad range of applications for this innovative thermal management technology,” Shrekenhamer said.

The ability to integrate advanced materials science, fabrication and optics and develop a state-of-the-art thermal management coating is a tribute to the Lab’s incredible collection of scientists and engineers,” Miragliotta added.

MEDIA CONTACT

Register for reporter access to contact detailsRELATED EXPERTS

David Shrekenhamer

Program Manager of Physics, Electronic Materials, and Device Research

Johns Hopkins University Applied Physics Laboratory